A recent article in This England magazine (a title firmly rooted in nostalgia and unashamedly so) focusses on Cussons, the soap manufacturer beloved by middle England housewives for its Imperial Leather bars.

A recent article in This England magazine (a title firmly rooted in nostalgia and unashamedly so) focusses on Cussons, the soap manufacturer beloved by middle England housewives for its Imperial Leather bars.

DOCUMENTING THE CRAFTSMANSHIP AND HISTORY OF PRODUCTS MADE IN THE BRITISH ISLES

A recent article in This England magazine (a title firmly rooted in nostalgia and unashamedly so) focusses on Cussons, the soap manufacturer beloved by middle England housewives for its Imperial Leather bars.

A recent article in This England magazine (a title firmly rooted in nostalgia and unashamedly so) focusses on Cussons, the soap manufacturer beloved by middle England housewives for its Imperial Leather bars.

Merry Christmas to all of our readers, we really appreciate you visiting the site. We're looking forward to 2011 and have some interesting pieces coming up, including; a field trip to a factory, an interview with the chief of the British Fashion & Textile Industry and a first look at some newly produced ties made in Britain.

Merry Christmas to all of our readers, we really appreciate you visiting the site. We're looking forward to 2011 and have some interesting pieces coming up, including; a field trip to a factory, an interview with the chief of the British Fashion & Textile Industry and a first look at some newly produced ties made in Britain. A nice little piece by Kate Watson-Smyth in The Independent today on the Ercol Butterfly chair. Here's the pick of the quotes:

A nice little piece by Kate Watson-Smyth in The Independent today on the Ercol Butterfly chair. Here's the pick of the quotes:

We recently came across this excellent case study on Anglepoise, courtesy of the Design Council:

We recently came across this excellent case study on Anglepoise, courtesy of the Design Council:Anglepoise is run by father and son team, John and Simon Terry. By 2001, the pair realised that if Anglepoise was to survive it was time to make a few harsh decisions. The most straightforward option, and one chosen by many UK manufacturers in recent years, would be to stick to the same products and distribution channels but move all production overseas – probably to China.

But the Terrys could see that this strategy might easily erode one of the company’s key remaining strengths – its reputation for precision design and engineering excellence.

‘Our margins were very small, and shrinking fast,’ explains Managing Director Simon Terry. ‘But we had a strong name, as well as our flawless design and engineering credentials. We wanted to find a way to reinvent the business to capitalise on these assets – not undermine them.’ There had to be another way.

The answer turned out to be a much more radical overhaul of the entire business. Anglepoise would start again, in a new location, as a high design, premium priced brand addressing an international marketplace.

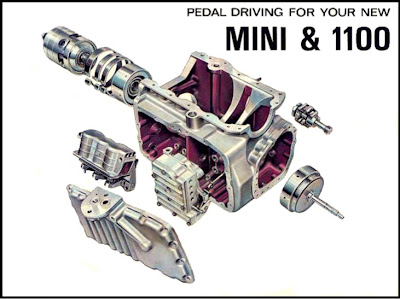

Image from the excellent looking John's Adverts

A recent short article in The Economist highlights the all too familiar issues surrounding the production of Fair Isle garments. Here are a couple of choice quotes:

A recent short article in The Economist highlights the all too familiar issues surrounding the production of Fair Isle garments. Here are a couple of choice quotes: An enjoyably positive story to kick off December here. The Highgate Brewery in Walsall has been saved (for the time being) and is hoping to benefit from customers drinking at home over the Christmas period after a surge in demand for its five litre festive cask ales.

An enjoyably positive story to kick off December here. The Highgate Brewery in Walsall has been saved (for the time being) and is hoping to benefit from customers drinking at home over the Christmas period after a surge in demand for its five litre festive cask ales.