Thursday, 22 December 2011

Monday, 19 December 2011

WEEKLY DIGEST

Articles of note on UK making that I have read this week:

On Tunnock's factory in Uddingston c2008 (Nothing To See Here)

At a cashmere mill in West Yorkshire (SEH Kelly)

Alan Sugar on UK manufacturing (Make it British)

Photo from SEH Kelly

Labels:

ALAN SUGAR,

CASHMERE,

MCLAREN,

SEH KELLY,

TUNNOCK'S,

WEEKLY DIGEST,

YORKSHIRE

Wednesday, 14 December 2011

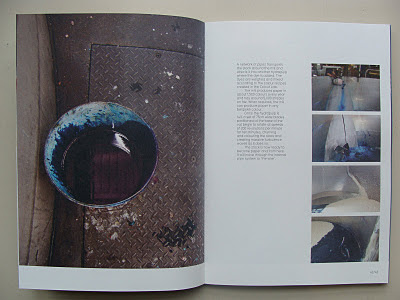

MOHAIR MILL, YORKSHIRE : SEH KELLY

SEH Kelly has recently published these photos of one of the mills it uses to produce its clothing range. Alongside the pictures is an insightful write up which includes this passage on how the mills in the Heavy Woolen District draw strength from each other:

SEH Kelly has recently published these photos of one of the mills it uses to produce its clothing range. Alongside the pictures is an insightful write up which includes this passage on how the mills in the Heavy Woolen District draw strength from each other:"Whereas a half century ago the mills here were competitors, now alliances of a type are commonplace. In place of inter-mill rivalry is recognition that cooperation and a pooling of the expertise that remain are in everyone’s best interest."

Labels:

CLOTHING,

SEH KELLY,

Textile design,

YORKSHIRE

Sunday, 11 December 2011

WEEKLY DIGEST

A video interview with Evin O'Riordin of the Kernel Brewery in Bermondsey, south London (Eat Big Fish)

On a beer note: Ten UK breweries causing ripples in 2011 (Food and Drink Digital)

A visit to the Fox Flannel factory (Permanent Style via Make it British)

Fallow denim weaving its own in London (Fallow Denim)

A visit to the Fox Flannel factory (Permanent Style via Make it British)

Fallow denim weaving its own in London (Fallow Denim)

Great piece on Margaret Calvert and Jock Kinneir's British road signs as design classic (BBC)

Kraft to make biscuits in the UK but Cadbury chocolate jobs seemingly at risk (Shropshire Star)

Thursday, 8 December 2011

HARRIS TWEED : FROM LAND TO STREET, BY LARA PLATMAN

"Our world is increasingly one devoid of reality and humanity. As our lives are played out over the ether - by electronic mail and instant message, in online shops - we are becoming detached from what is real and substantial and true," writes Patrick Grant in the foreword to this stunning book of photographs by Lara Platman.

"Our world is increasingly one devoid of reality and humanity. As our lives are played out over the ether - by electronic mail and instant message, in online shops - we are becoming detached from what is real and substantial and true," writes Patrick Grant in the foreword to this stunning book of photographs by Lara Platman.The book was published to coincide with the 100th anniversary of Harris Tweed's trademark Orb stamp and is a fitting tribute to the only fabric that has its own legislation. 'Harris Tweed means a tweed that has been hand-woven by the islanders at their homes in the Outer Hebrides, finished in the Outer Hebrides, and made from pure virgin wool dyed and spun in the Outer Hebrides' goes the definition which became statutory when it was passed in 1993.

Having endured a fall in demand during the 90s and early part of this century, the Harris Tweed industry has steadied, meaning there is demand for weavers once again.

Covering the entire process - from wool to mill to weaver and on to finished article, Platman introduces the reader to some of the people who have benefitted from the resurgence of this beautiful material. Alongside some good portrait photos of the weavers, mill workers and farmers, are short descriptions of their daily lives and working ways.

The book provides a suitable entry level of detail. Details on the different sheep breeds tell the reader about Blackface sheep - dating from the 12th century and the original wool source for Harris Tweed. Nowadays Scottish cross breeds and Cheviot sheep from the Borders are used. These allow for softer tweeds to be produced, meeting modern demand for such fabrics.

"I hope... that my depiction of those who work with Harris Tweed will be a reminder of some of the skills that are alive in Britain today," writes Platman in her introduction. Harris Tweed: From Land to Street is more than a reminder. It is a celebration of the production of one of Britain's finest items. And it certainly has the substance and truth that Patrick Grant mentions in his foreword.

-

With thanks to Emma at Frances Lincoln

Labels:

BOOK REVIEW,

HARRIS TWEED,

LARA PLATMAN,

SCOTLAND,

SHEEP,

Textile design

Monday, 5 December 2011

QUOTE : TIM LITTLE, CREATIVE DIRECTOR & OWNER OF GRENSON

"Our founder, William Green... had begun by travelling to London and taking orders from the finest shops of the time. He would then come back to Rushden and give the work to the craftsmen who all worked from home. When each part of the shoe was ready he would pick them up and take them to the next house where the next phase of the process was completed. After a few years his business had grown enough to create the need for a factory where the workers could come in and work together in a production line, thus making the process quicker and more efficient. We are currently in his second factory, that he built in 1895. "William Green and son" was shortened to Grenson at the start of the 20th century amid a fashion for "brand names"."

Photo from Harrison A

Labels:

GRENSON,

NORTHAMPTON,

QUOTE,

SHOEMAKING,

TIM LITTLE

Sunday, 4 December 2011

WEEKLY DIGEST

Inside the Carradice factory, Nelson, Lancashire. Brilliant slideshow and interview with owner and MD, David Chadwick (The Bike Show)

Four great posts, featuring factory visits in Sussex by artist Carly Mayer. Personal favourite is the ratchet strap (Sight Unseen)

100 Secrets of Mackintosh: 100 interviews with 'tastemakers' about the brand (Renaissance Chambara)

Dyson vs China in intellectual property row (Guardian)

Nice piece on young talent in farming (Telegraph)

Labels:

AGRICULTURE,

CARRADICE,

CLOTHING,

cycling,

DYSON,

MACKINTOSH,

THE GUARDIAN,

THE TELEGRAPH

Thursday, 1 December 2011

JAMES CROPPER SPECIALITY PAPER : PULP-PAPER BOOK

Recently, I received a beautifully packaged book from Mark Cropper, chairman of James Cropper Speciality Paper.

The book is entitled Pulp-Paper and was launched in the summer of 2010. The book is the result of a question: "Can we see how your paper is made?" It is a joint project between James Cropper Speciality Paper, GF Smith, Generation Press and design studio KentLyons.

Over 128 pages, the authors explain how James Cropper makes some of the papers contained in the book. There are also ruminations on the joy of paper from a range of design folk, including Patrick Burgoyne of Creative Review and Nat Hunter of Airside.

Pulp-Paper is available from the Design Museum shop

-

Further reading:

James Cropper in Monocle Issue 42, April 2011 (links to PDF which includes breakdown of paper making process)

James Cropper Plc - the development of a modern paper manufacturer by Duncan Hutt in The North West Mills Group Newsletter 45 (1995)

Labels:

BOOK REVIEW,

BRITISH DESIGN,

CUMBRIA,

GENERATION PRESS,

GF SMITH,

JAMES CROPPER,

KENTLYONS,

London,

PAPER MAKING

Subscribe to:

Posts (Atom)